Formed Mfg provides fast domestic CNC machining

The need for domestic manufacturing

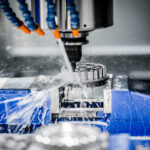

The past few decades have seen a dramatic shift in the landscape of American manufacturing. Once the world leader in output, the United States has fallen behind as other countries have taken advantage of lower labor costs and fewer regulations. This has led to the loss of millions of jobs and left many American communities struggling. However, there is a growing movement to bring manufacturing back to the United States, and cnc machining is a crucial part of that effort. Cnc machining is a form of computer-aided manufacturing that allows for highly precise production of metal parts. It is used in a wide range of industries, from aerospace to medical devices, and its precision and efficiency make it ideal for domestic manufacturing. Bringing cnc machining back to the United States will create jobs and help revive our manufacturing base. It is an essential part of rebuilding America’s manufacturing strength.

The current state of domestic manufacturing

The slow turn around and lead times for domestic manufacturing have been a cause for concern for many businesses. Companies are increasingly exploring ways to improve the efficiency of domestic production, in order to stay competitive in their respective industries and meet the growing demand from consumers. Companies can explore a range of production methods, from automation and robotics, to streamlining processes and better utilizing resources. In addition, partnerships with other businesses within the supply chain can further drive down costs while still producing quality products. Ultimately, companies must be innovative to successfully navigate through the current state of domestic manufacturing and remain successful in the long-term.

The benefits of domestic manufacturing

Manufacturing at home can provide numerous benefits for both businesses and consumers alike. Domestic manufacturing ensures export compliance, allowing companies to know that the goods they export are up to the required safety and quality standards. Additionally, businesses can reduce overhead costs associated with overseas production, while providing jobs and stimulating local economies. Finally, customers benefit from shorter lead times on orders and improved product quality when purchasing domestically-made products. All in all, domestic manufacturing provides important economic and legal benefits to businesses and consumers alike.

The challenges of domestic manufacturing

Domestic manufacturing can present many challenges for companies sourcing raw materials. It is important to investigate multiple sources of raw materials with regards to availability, pricing, and proximity to the production facility, as these factors can have a large effect on production costs and turnaround times. Internal vertical integration may also need to be considered where sourcing arrangements require special considerations such as sustainability targets or ethical sourcing protocols. By understanding all facets of the purchasing process of raw materials, domestic manufacturers are better prepared facing any eventuality.

The future of domestic manufacturing

In today’s fast-paced and tech-savvy world, domestic manufacturing must find a way to speed up processes while still creating products that are of high quality. To keep up with the demand for faster delivery of goods, companies must adopt improved practices that both prioritize and optimize efficiency. New technologies such as automation and predictive analytics enable manufacturers to streamline their operations, leading to decreased production time and cost savings. Ultimately, those invested in domestic manufacturing face an exciting challenge: to create the most efficient system possible while meeting the demands of customers in a global market driven by innovation. Let Formed Mfg help you speed up your product development and prototyping today!